|

Dawg’s idler pulley project |

Post Reply

|

Page 12> |

| Author | |

Dawg

Senior Member

Joined: 15 August 2009 Location: Canada Status: Offline Points: 988 |

Post Options Post Options

Quote Quote  Reply Reply

Topic: Dawg’s idler pulley project Topic: Dawg’s idler pulley projectPosted: 16 January 2011 at 11:16pm |

|

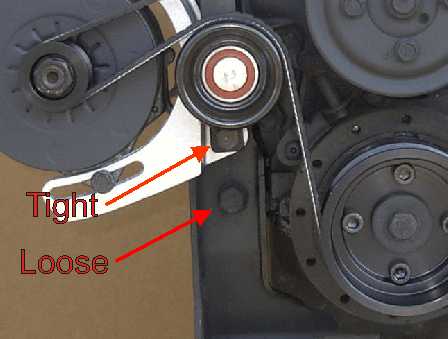

I've decided to start building one of those idler wheels for the alternator belt. I have a belt on the car now that is much less than a year old and it's starting to squeal already. What a pain.

So here we go. Because I already had the bearings and steel, I decided to make a dual bearing wheel. Should last forever that way. Here is the shoulder bolt I made from a larger bolt. It's shoulder lets it act like an axle without "pinching" the bearings. Next I need to make the bracket. Then I will trial fit everything to determine where I want the wheel to sit and how thick the spacer will need to be to center the belt. Ideally a simple washer will do. Stay tuned. |

|

|

You dream it up....I'll make it

|

|

|

|

kharmata

Senior Member

Joined: 19 April 2010 Location: Canada Status: Offline Points: 291 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 17 January 2011 at 11:41am Posted: 17 January 2011 at 11:41am |

|

Looks Heavy Duty.

|

|

|

|

Capt Fiero

Admin Group

Founding Member Joined: 12 February 2007 Location: Canada Status: Offline Points: 4039 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 17 January 2011 at 1:08pm Posted: 17 January 2011 at 1:08pm |

|

gesus man is that a pulley or a flywheel LOL. :) Ya I'd say that will last forever, and probably keep the engine running if it dies for a second. |

|

|

Capt Fiero

88 Fiero GT 5spd V6 Eight Fifty Seven GT V8 5spd. |

|

|

|

Dawg

Senior Member

Joined: 15 August 2009 Location: Canada Status: Offline Points: 988 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 19 January 2011 at 3:48pm Posted: 19 January 2011 at 3:48pm |

|

Hehehe Perfect....next time the fuel pump dies I can just coast all the way home.....Bonus!

The Dawg

|

|

|

You dream it up....I'll make it

|

|

|

|

Dawg

Senior Member

Joined: 15 August 2009 Location: Canada Status: Offline Points: 988 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 19 January 2011 at 4:19pm Posted: 19 January 2011 at 4:19pm |

|

I'm coming down the home stretch. I finished the bracket this afternoon but then realized the water pump is worn out. So installing the idler will have to wait till I get the new pump in there tomorrow.

A note to Kevin: bolts are rated by their shank diameter's, not the head sizes....:) Here's the final assembly. Look closely and you will see that I slotted the mounting holes. This will allow some up and down adjustment which could come in handy. If I make more of these I'm considering slotting them even more. We'll see. I can't wait to see it all finished. Anything like this that makes the car more reliable is such a feel good project. Wasn't expensive either. Well, after I pay for the the new water pump and alternator I may not feel quite the same....:) The Dawg |

|

|

You dream it up....I'll make it

|

|

|

|

kharmata

Senior Member

Joined: 19 April 2010 Location: Canada Status: Offline Points: 291 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 19 January 2011 at 5:04pm Posted: 19 January 2011 at 5:04pm |

|

Thanks Damien - I think I noted the head sizes from when I

wrenched it on. I didn't realize I left them on the picture in the post. LOL! As for your design - it looks great. 'My personal concern' would be the likely hood of twisting the thin cross bracket. With the small diameter standoff that looks to give it a fairly good mechanical advantage and may not like tight belts or quick throttle ups. I would suggest a wider base that the bearing sits on. But that's just from what I see in the pictures. Cheers |

|

|

|

ZeroC

Senior Member

Joined: 12 February 2007 Location: Canada Status: Offline Points: 346 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 19 January 2011 at 7:39pm Posted: 19 January 2011 at 7:39pm |

|

i have the rodney dickman one on my car ....and honestly it works great for a week ..then i have to tighten the alt agian ...starts to get a lil squeek in the rain ...very annoying..im going to look at an actual tensionor now ...one a side note that looks well built :)

|

|

|

|

|

|

kharmata

Senior Member

Joined: 19 April 2010 Location: Canada Status: Offline Points: 291 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 19 January 2011 at 7:52pm Posted: 19 January 2011 at 7:52pm |

So you are saying ... bolts don't have head sizes...?

|

|

|

|

Dawg

Senior Member

Joined: 15 August 2009 Location: Canada Status: Offline Points: 988 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 19 January 2011 at 9:16pm Posted: 19 January 2011 at 9:16pm |

|

You could be right Kevin. On the day I'll have to keep an eye on the flexing for sure. It feels pretty darn rigid however. Like most days, I built it with what I had in the metal bin....:)

It would be easy to modify either way. If you look at your diagram, which I used as a guide thank you, you mention drilling clearance holes for 17 and 15mm bolts. Those would be huge bolts indeed. I believe those bolts are 12mm actually. (shank diameter) |

|

|

You dream it up....I'll make it

|

|

|

|

kharmata

Senior Member

Joined: 19 April 2010 Location: Canada Status: Offline Points: 291 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 19 January 2011 at 9:20pm Posted: 19 January 2011 at 9:20pm |

|

9/16 would also work.

Nothing to hurt by trying. Nothing to hurt by trying.

Just make it work however you can i say.

|

|

|

|

Dawg

Senior Member

Joined: 15 August 2009 Location: Canada Status: Offline Points: 988 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 23 January 2011 at 12:54pm Posted: 23 January 2011 at 12:54pm |

|

I went to put the assembly on last night and I ran into a few snags. For starters, I think I'm going to have to back pedal a bit regarding the offset. With the water pump off, it sure looks like the bolts indeed are offset by quite a bit after all. I measured a little over 3/8". Originally I placed the bracket on the bolt heads and looked down to see if it was parallel to the belt. It seemed to be.

I'm going to wait till I actually get it mounted before spewing numbers this time....:) A couple more snags came up also. I tried to remove the lower bolt with a large 3/8 ratchet and no way. I was pressed for time so decided to tackle it another day. I had already installed a new water pump and alternator and it was getting dark and spooky. Then I noticed the bolt right below it was not tight.  I've never been down this low on the motor. Could my problem be that the weight of the motor is sitting on the top bolt? I tried to tighten the bottom one but it appears to be bottoming out. I'll have to dig a bit when the sunshine returns. The Dawg |

|

|

You dream it up....I'll make it

|

|

|

|

kharmata

Senior Member

Joined: 19 April 2010 Location: Canada Status: Offline Points: 291 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 23 January 2011 at 3:32pm Posted: 23 January 2011 at 3:32pm |

|

ok - good to know, I will update my sketch too when you

measure an offset. Not sure why you can't get it out. Other than being in a really tight spot to reach. So too confirm the offset is inwards at the bottom right? or is it out...i forget.

|

|

|

|

Dawg

Senior Member

Joined: 15 August 2009 Location: Canada Status: Offline Points: 988 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 23 January 2011 at 8:29pm Posted: 23 January 2011 at 8:29pm |

|

Yes, the bottom leg will need to be longer.

The Dawg |

|

|

You dream it up....I'll make it

|

|

|

|

kharmata

Senior Member

Joined: 19 April 2010 Location: Canada Status: Offline Points: 291 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 24 January 2011 at 6:00pm Posted: 24 January 2011 at 6:00pm |

Can you clarify - whats a little over 3/8"? Thanks. |

|

|

|

Dawg

Senior Member

Joined: 15 August 2009 Location: Canada Status: Offline Points: 988 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 24 January 2011 at 11:15pm Posted: 24 January 2011 at 11:15pm |

|

I'm estimating 3/8. It really isn't that critical.

The Dawg |

|

|

You dream it up....I'll make it

|

|

|

|

Dr.Fiero

Senior Post God

Joined: 12 February 2007 Location: Canada Status: Offline Points: 1726 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 25 January 2011 at 5:41am Posted: 25 January 2011 at 5:41am |

The entire weight of the engine bears on those two bolts! (on an early car) So, you need to prop it up on a jack (etc) if both are coming out at the same time. |

|

|

|

Dawg

Senior Member

Joined: 15 August 2009 Location: Canada Status: Offline Points: 988 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 04 February 2011 at 10:11pm Posted: 04 February 2011 at 10:11pm |

|

I had some spare cash last week so I was able to fill up my Argon tank. This means TIG welding time!

I modified the bracket to include a 3/8" offset between the two mounting points. It sure looks like a lot but the ruler don't lie. Hopefully this will lend itself to perfectly even pressure across the whole belt. Also, since I was making a fairly major modification anyway, I decided to add some rigidity as Kevin suggested. This came in the form of two gussets. Rather than upload the images in this message I simply updated the originals above. If it's nice this weekend, I'm going to try and get it all installed. The Dawg |

|

|

You dream it up....I'll make it

|

|

|

|

kharmata

Senior Member

Joined: 19 April 2010 Location: Canada Status: Offline Points: 291 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 05 February 2011 at 9:18am Posted: 05 February 2011 at 9:18am |

|

It sure looks custom now.

Nice Job! Nice Job!

|

|

|

|

Dawg

Senior Member

Joined: 15 August 2009 Location: Canada Status: Offline Points: 988 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 05 February 2011 at 2:45pm Posted: 05 February 2011 at 2:45pm |

|

Thanks! I'll get it right eventually...:)

The Dawg |

|

|

You dream it up....I'll make it

|

|

|

|

kharmata

Senior Member

Joined: 19 April 2010 Location: Canada Status: Offline Points: 291 |

Post Options Post Options

Quote Quote  Reply Reply

Posted: 06 February 2011 at 10:10am Posted: 06 February 2011 at 10:10am |

Won't we all.

|

|

|

|

Post Reply

|

Page 12> |

| Tweet |

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |