Wheel offsets and spacer plates

Printed From: West Coast Fieros

Category: Technical Topics Forum

Forum Name: Technical Questions and Discussions

Forum Description: Got a technical question about your fiero? ask it here.

URL: http://www.westcoastfieros.com/forum/forum_posts.asp?TID=2547

Printed Date: 03 April 2025 at 1:32pm

Software Version: Web Wiz Forums 12.01 - http://www.webwizforums.com

Topic: Wheel offsets and spacer plates

Posted By: Patrick

Subject: Wheel offsets and spacer plates

Date Posted: 27 June 2011 at 11:18pm

|

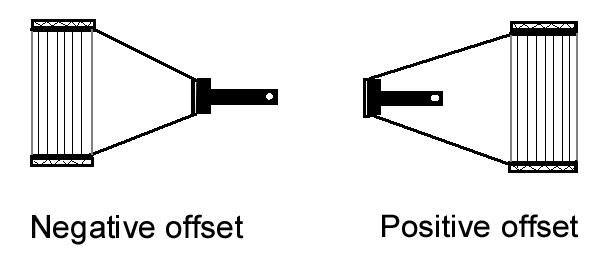

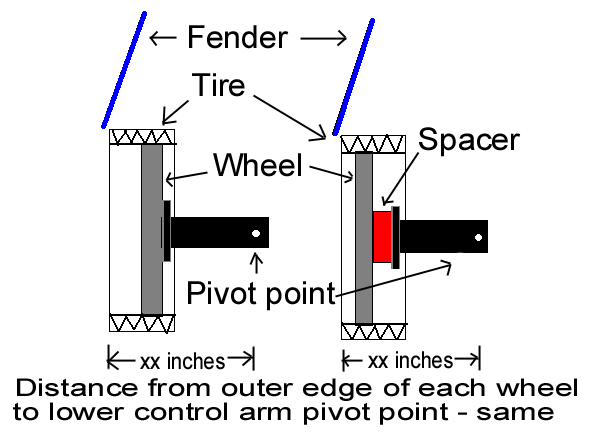

I have heard that using wheel spacers puts extra stress on wheel bearings. Yes, I agree that as a wheel is moved further away from the hub, this increases the leverage and therefore the stresses placed on the bearings. Are we all in agreement on that? Last Saturday while helping with my suspension mods, Tristan was bugging me (in a friendly manner) about the Sunfire rims on my '84, saying that they had too much positive offset. This results in the wheels/tires being tucked into the fender more than the factory Fiero wheels. It's not bad in the front, but I agree it's more noticeable in the back. I said I wanted to use a spacer to move the rear wheels back out towards the edge of the rear fender, and Tristan mentioned about this being bad for the bearings etc. But is it? Tristan and I debated the issue and got nowhere. I felt it was too difficult to visualize and discuss without a diagram. So here it is. The point I was trying to make with Tristan, and he couldn't see it, was that if you move a positive offset wheel out with a spacer, it's no different than using a wheel which has a more negative offset as long as the end result is the same. By "end result", I'm referring to where the wheel/tire is in relation to the fender, or in relation to the pivot point of the lower control arm. Looking at the diagram below (which I know is not drawn "correctly"), if the wheel on the left is a stock Fiero rim, and the wheel on the right is a Sunfire rim (with more positive offset) being used with a spacer, can anybody tell me that this is going to make ANY difference in regards to what stresses the wheel bearings will experience? I say in this situation the stresses on the bearings are exactly the same as each wheel/tire ends up in the same location relative to the car/suspension. Comments?

|

Replies:

Posted By: Colby

Date Posted: 27 June 2011 at 11:40pm

As far as I can tell, yes it would. The left hand wheel has it's centre of mass closer to the pivot point. Torque = R x F where R is the distance from the pivot to centre of mass of the wheel and F is the mass * 9.8. The greater R of the right hand side wheel means more torque applied to the bearings. ------------- 88 Formula 5 speed |

Posted By: Romeo

Date Posted: 27 June 2011 at 11:52pm

|

As Colby mentioned, the mass is essentially being held "further out" from the hub. The weight is worth more force (Consider ten pounds of thrust held six inches away from the head of a ratchet versus ten pounds held a foot away; The second will transfer more force) ------------- Never shift into reverse without a back-up plan. |

Posted By: Patrick

Date Posted: 28 June 2011 at 12:09am

|

Tristan, you posted while I was typing out my response to Colby. What you've stated ties in exactly to what I was about to post... Colby, it's been a lot of years since my high school physics classes, so I'm at somewhat of a disadvantage here! I have to admit I don't know about the need to take into consideration the "center of mass". I thought it would be more along the lines of how a lever works. The longer the lever, the more force applied. In this case, the lever would be the tire on the ground and the lower control arm working against the coil spring. The force being applied to the lever is the weight of the car pushing against the road. The end of the lever is the outer edge of the tire. In both examples I've pictured above, the "end of the lever" is the same distance from where the lower control arm pivots. With that in mind, the forces working against the wheel bearings would be the same IMO. Colby, you very well may be right, but I'm still not willing to conceed until I come across something "official".

|

Posted By: Romeo

Date Posted: 28 June 2011 at 12:36am

|

But the tire is not where the weight is being applied to the bearing - the inner face of the rim is. As for picturing it as a simple lever - that's fine. But how you're picturing it is going about it wrong. The part of the rim where the lug nuts actually press down on, that's where the torque is applied to the bearing. By moving it out, you are increasing the net torque by means of increased leverage. ------------- Never shift into reverse without a back-up plan. |

Posted By: Colby

Date Posted: 28 June 2011 at 12:39am

Actually, what I'm describing is exactly how levers work. In this case it's rotational force being applied (torque).

For the sake of clarity, I was focusing on simply the torque applied to the bearing from the wheel. There are two important "levers" here, one from the tire to the bearing and one from the ball joint on the control arm to where the control arm bolts to the cradle. Since we are concerned with the stresses on the bearing, it's pretty safe to ignore the second lever. ------------- 88 Formula 5 speed |

Posted By: Colby

Date Posted: 28 June 2011 at 1:14am

|

Pat, I think the question you should be asking is not whether there actually is additional stress but rather, something like: "should I be concerned about additional stress leading to premature failure of the bearings?". I think so long as the wheels aren't overly heavy you would probably be fine. Although I have no experience with them, I'd probably be seeing more results about failed bearings in the Google searches I've done tonight if it was a common problem. ------------- 88 Formula 5 speed |

Posted By: Patrick

Date Posted: 28 June 2011 at 1:20am

|

Hmmm... it's possible what I'm not understanding then (and taking into consideration) is the rotational torque. All I've focused on is the weight of the car on the bearings. I wasn't even thinking of power being applied to the wheels through these same bearings, and of course the wheels spinning. Okay, I'll have to ponder this now. Thanks guys.

|

Posted By: Patrick

Date Posted: 28 June 2011 at 1:26am

|

Yeah, when you consider the huge wheels and tires that Johnny has on his car, and his SC3800... and he has something like two inch spacers installed!

|

Posted By: Colby

Date Posted: 28 June 2011 at 1:31am

Actually I was ignoring the rotation of the wheel and I'd prefer not to

get into it. The torque (rotational torque is redundant as all torque is

rotational) I'm referring to is what causes the slight deflection in the first lever I

described and it's caused by the weight of the wheel and it's location on the hub. ------------- 88 Formula 5 speed |

Posted By: Patrick

Date Posted: 28 June 2011 at 2:12am

|

Give me a break. It's late and I'm old.

|

Posted By: Dawg

Date Posted: 28 June 2011 at 3:09am

|

I think Tristan explained it more plainly and he is right. This lever we are the most concerned about starts where the wheel meets the hub and ends on the inner most side of the bearing. Try to imagine this bearing right inside the center of the wheel. In that case, the weight of the car is pushing straight down on the bearing. This would be ideal. Every inch away from this ideal gives mechanical advantage to the car. Not good. Add to that braking and accelorating (sp?) forces which are many times more severe than the others and you are asking for trouble. For the record, poor Johny has had plenty of problems due to his spacers and wide rubber. I would venture to say that if he drove his car like I like to drive. it wouldn't last a month, never mind autocross. My advice, don't do it. The Dawg ------------- You dream it up....I'll make it |

Posted By: Car-2-Lo

Date Posted: 28 June 2011 at 7:46am

|

For the RECORD, I had no problem with the 1-1/4" wheel adapters on the rear,

some asshole didn't check for LOOSE NUTS http://www.youtube.com/watch?v=zBFMLyZ23Wc - HERE ------------- Johnny-B-Good

|

Posted By: Colby

Date Posted: 28 June 2011 at 8:08am

I agree that the stresses occur during braking and accelerating, as well as whenever the suspension travels. The thing I don't like about the explaination where you're only concerned with where the start of the rim mounts to the hub and it's distance from the bearing is this: For the sake of argument, what happens if you were to weld the spacers on to the wheel? Does this now mean that the wheel is now mounted directly against the hub? If the spacer is now apart of the rim, then the rim is now mounted right up to the hub and by your explaination (assuming I am understanding correctly) the negative effects should now be mitigated. That seems doubtful to me, and taking into consideration the location of the centre of mass of the wheel gets around this nicely. ------------- 88 Formula 5 speed |

Posted By: Dawg

Date Posted: 28 June 2011 at 9:38am

|

You make a valid distinction here. I was assuming that the spacer was part of the hub, since it is bolted to the hub not the wheel. So assuming this, my explanation would still work no? I'm not so sure about the center of mass negating the leverage however. This in a sense is what Patrick is suggesting. He is wondering if having the center of mass right over the bearing would counteract the effects of the spacer. I think not. Ignoring cornering effects, the same amount of vehicle weight is present. Would you agree? The Dawg

------------- You dream it up....I'll make it |

Posted By: Dawg

Date Posted: 28 June 2011 at 9:49am

|

To be honest Johny, most of the issues I've read about have been regarding the front suspension not the back. The theory is the same however. I personally think that your cool setup is hard on your bearings and suspension parts and contributed to your worn out parts. This simply means you have to be aware of it and be extra attentive to maintenance. No different than any other performance car I suppose. All I'm trying to say is no spacer would be better is all. How much better? I'm not sure. The Dawg ------------- You dream it up....I'll make it |

Posted By: Car-2-Lo

Date Posted: 28 June 2011 at 10:20am

|

GET YOUR STORY STRAIGHT guys.. about poor Johnny and yes I agree about more stress on bearings ! For the RECORD, I had no problem with rear wheel bearings using 1-1/4" wheel adapters on the rear, some asshole didn't check for LOOSE NUTS http://www.youtube.com/watch?v=zBFMLyZ23Wc - HERE I had no problems with wheel bearings, just ALIGNMENT SHOPS (LOOSE NUTS) ! I only got Capt to change BEARINGS because they where 25years old, but look what he found (from DALES ALIGNMENT) LOOSE NUT !!!!!

Found one bad (cheap) bearing right out of the box and replaced it with my old bearing and I'm still driving with it and one cheap bearing. Since then I got two new costly bearings that I'll be installing next week when doing the bump steer suspension and keep the old ones for spares. Hugh has spacers front and back with turbo V8 power, will see how that works out ?

------------- Johnny-B-Good

|

Posted By: Car-2-Lo

Date Posted: 28 June 2011 at 10:44am

I agree with you all about more stress on bearings, but actually I never had that problem yet

As you can see me being paranoid, checking all nuts and bolts and yes the new bump steer suspension will be high maintenance, but that's okay, that's my hobby. ------------- Johnny-B-Good

|

Posted By: Romeo

Date Posted: 28 June 2011 at 11:21am

|

There are three things to consider with regards to spacers: Spacer size (Mechanical advantage), tire and rim weight (Mechanical force) and driving style/road condition (Additional shock force). Johnny Boy might be able to get away with large rims and spacers because he is a sane driver. During autocross conditions, where we have the rough road and hard braking and acceleration, those forces will now really compound the existing stress.

As for your thought-question about welding the spacers, I can't imagine why it would help. The weight is still being held away from the hub; That torque still maintains a mechanical advantage. ------------- Never shift into reverse without a back-up plan. |

Posted By: Car-2-Lo

Date Posted: 28 June 2011 at 11:27am

Well Dawg, that's why you're NOT driving Michele's old 2M6 anymore, IT DIDN'T LAST AT ALL, never mind autocross

So you see for THE RECORD, I had no problems at all due to spacers, it was all DUE to asshole ALIGNMENT SHOPS not doing there job

------------- Johnny-B-Good

|

Posted By: Patrick

Date Posted: 28 June 2011 at 11:57am

|

Damien, I'm NOT chastising you (honest), but that wasn't the best comment to post after all the hassle that Johnny was forced to endure at the hands of "professionals". Yes, Johnny has had plenty of problems with his rear suspension, but it was well documented here that it was due to negligence by two alignment shops. The first one, Dale's, didn't tighten the tie rod lock nut, and the second, Tru-Line, didn't even notice before doing their alignment that the rear ball joints were just flopping around as the mounting nuts/bolts had never been tightened! We've all seen http://www.youtube.com/watch?v=zBFMLyZ23Wc - The video that Johnny posted. There was NO excuse for a "reputable" shop missing that (and then compounding the issue by refusing to acknowledge and/or correct their screw-up). Johnny's suspension problems had NOTHING to do with the use of wheel spacers. Yes, there's obviously still some bitterness felt by many of us over that whole unfortunate experience.

|

Posted By: Patrick

Date Posted: 28 June 2011 at 1:00pm

|

Okay, back to the original topic... I'm glad to see there has been some good discussion generated over the question of using spacer plates. I'm still trying to get my head around the issue of stress on the bearings due to the distance of the wheel from the hub. The argument seems to be that it's the extra distance from the hub due to the spacer plate that creates this extra stress, as opposed to what I was suggesting that the extra stress was due to the distance from the outside edge of the wheel/tire (the end of the "lever") from the pivot point of the lower control arm. Here's another diagram. Both wheels are mounted to the hub (no spacer plates). The wheel on the left has extreme negative offset, the wheel on the right has extreme positive offset. I suspect there is a whole lot more stress on the wheel bearings on the left wheel as the leverage from the outside edge of the wheel/tire to the pivot point is MUCH greater than the leverage created by the wheel pictured on the right. If I'm understanding you guys correctly, you're going to tell me there is no difference between these two examples in regards to stress on the wheel bearings. Is that correct?

|

Posted By: Dawg

Date Posted: 28 June 2011 at 1:01pm

|

It's just my opinion guys. I was there, trying to help diagnose the problem to help out a friend. I think I'm entitled to an opinion. Any more to say on this? Please PM me. As for the spacer issue on your car Patrick, the car you intend on using for autocross, I'm giving you the best advice I know how to give. Use it as you see fit. Cheers, Dawg

------------- You dream it up....I'll make it |

Posted By: Dawg

Date Posted: 28 June 2011 at 1:22pm

|

I've obviously hit a nerve here. Sorry Johnny. It's apparent that there is nothing holding anyone back from spacers then. Patty, you first....:) The Dawg ------------- You dream it up....I'll make it |

Posted By: Colby

Date Posted: 28 June 2011 at 2:19pm

There's always a certain amount of risk involved when you modify a car from it's original specs. Patrick ended up riding on his bump stops last time he did it so it's probably a wise choice to be a bit more cautious this time.

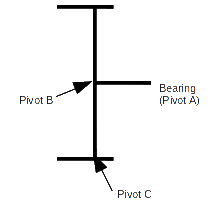

I've given the problem a bit more thought and there's a few things I think I should mention. In my original example I was looking at the vertical forces only, so hopefully that makes a bit more sense if it didn't already. I also maybe simplified it a bit too much. What I described originally is that the centre of mass of the wheel is further outward which causes more torque on the bearing. Let's try to simplify the system a bit by looking at it two dimensionally and only looking at the vertical forces. The system can be represented by 4 rods connected like this:  In order for the bearing to be stressed (for there to be a torque at the bearing), there must be a vertical force applied to where the long middle rod connects to the what would be the hub (at Pivot B). Where does the force come from? It seems like it'd be primarily from the car bouncing along the road. I'd argue that the forces applied to the outside edge of the wheel mostly end up causing torque at pivot C rather than at the bearing and that the manufacture of the wheel takes this into consideration and makes the wheel able to withstand this. ------------- 88 Formula 5 speed |

Posted By: Romeo

Date Posted: 28 June 2011 at 8:15pm

|

Citing your example Patty, yes, both bearings would be stressed equally. The force of torque would be going straight in to the hub. Now, a positive offset plus spacer causes this stress to travel through a mechanical advantage, applying more torque when it reaches the bearing. If I'm not mistaken, this torque typically applies to the top of the bearing, if that aids you in inspecting the bearings after. ------------- Never shift into reverse without a back-up plan. |

Posted By: Car-2-Lo

Date Posted: 28 June 2011 at 10:03pm

It's not holding me back and also Hugh's V8 TURBO, I always agreed with you all about having lots of stress on the bearings, what's the big deal, if they go, get new ones, but not the cheap ones  (I edited this, Johnny Boy, in the interest of everybody loving everybody else - Tristan) ------------- Johnny-B-Good

|

Posted By: Patrick

Date Posted: 28 June 2011 at 10:22pm

|

My opinion for what it's worth here is that I don't like "mods" editing member's posts. If it was my post that was edited I'd be plenty ticked.

|

Posted By: Patrick

Date Posted: 28 June 2011 at 10:29pm

|

Back on topic, again...

I guess what I'm going to have to do is to build a model of my diagram and see for myself if the forces are equal no matter what the offset of the wheels (or the length of the levers) are.

Sorry Colby, I don't understand the diagram.

|

Posted By: Romeo

Date Posted: 28 June 2011 at 10:33pm

|

I cannot deny being a touch confused by it myself. I'm sure it does make sense, it just needs an explanation, that's all. Anyways, we should make a small-scale experiment of it, would be interesting to see (Measuring the force will be hard, mind you). As for the edited post, consider it a matter of keeping the peace. Only time I've done it, and I don't intend to make a habit of it. ------------- Never shift into reverse without a back-up plan. |

Posted By: Colby

Date Posted: 28 June 2011 at 10:49pm

They're pivots, but that doesn't mean there is actually movement there, it just means torque is applied about those points. There is probably a better word for it. That's just my attempt to describe the system in a somewhat crude and simplified way using a bunch of rods (think of looking at a slice of the rim). ------------- 88 Formula 5 speed |

Posted By: Patrick

Date Posted: 28 June 2011 at 11:08pm

|

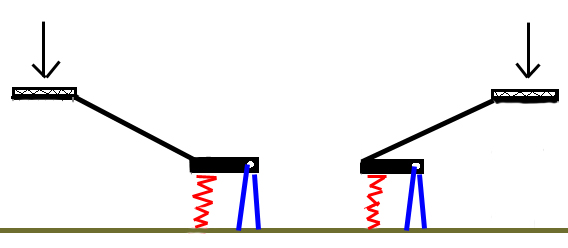

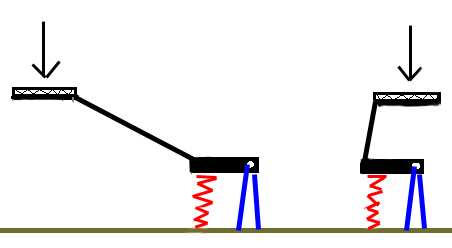

Here's my above diagram altered to show it as two levers. The red squigley things are springs. The blue things are legs for the pivot. I cannot believe that the force required to compress the springs X number of inches would be the same for both setups.

Same thing, but with less positive offset on the right hand lever.

Whether we're measuring the force required to compress the springs a prescribed distance, or measuring the compression of the springs as the result of an applied force, I can't see how there would be any way they'd be the same for both setups. No way. The same force (weight of car on road, moving or not) would compress the springs more in the left hand setup. In other words, the more the negative offset, the more force/stress there'd be on the wheel bearings. Colby, Tristan... explain the error in my thinking!

|

Posted By: Car-2-Lo

Date Posted: 28 June 2011 at 11:35pm

|

Great place to get spacers http://www.motorsport-tech.com/ - HERE ------------- Johnny-B-Good

|

Posted By: Colby

Date Posted: 28 June 2011 at 11:40pm

My diagram confused you and now your diagram is confusing me... lol.  Why do you care about the effect on the springs? Yes, the force required to compress the springs a certain amount would be different in each of those examples. ------------- 88 Formula 5 speed |

Posted By: Patrick

Date Posted: 28 June 2011 at 11:47pm

|

Colby, see what I've added to my last post.

|

Posted By: Colby

Date Posted: 29 June 2011 at 12:18am

|

I'm just confused now since I'm not quite sure what you're thinking. How about we talk about this at the autocross? I'd like to explain my thought process from the start again and doing it in person would let you interrupt me if I'm not making sense. ------------- 88 Formula 5 speed |

Posted By: Patrick

Date Posted: 29 June 2011 at 12:32am

|

Sure, that would be fine.

|

Posted By: Patrick

Date Posted: 29 June 2011 at 12:34am

|

Johnny, those spacers are worth more than my car! I need to check out the cheap Made in China eBay junk first.

|

Posted By: Car-2-Lo

Date Posted: 29 June 2011 at 8:38am

That's okay, I'll bring flowers for Dawg at next meeting, I love you

|

Posted By: Romeo

Date Posted: 29 June 2011 at 10:08am

LOL! Quote. Of. The. Year.  ------------- Never shift into reverse without a back-up plan. |

Posted By: Dawg

Date Posted: 29 June 2011 at 11:29am

|

hehehehe....If you bring flowers you'll get a hug.....<blush> The Dawg

------------- You dream it up....I'll make it |

Posted By: Car-2-Lo

Date Posted: 30 June 2011 at 7:44am

That's not all Damien, now the club want us to sit together

|

Posted By: Car-2-Lo

Date Posted: 30 June 2011 at 10:22am

Hey Patty, Brian has really nice 17"s for your ride, they will look and perform better than those girly wheels

|

Posted By: Patrick

Date Posted: 20 July 2011 at 12:43am

|

Would those necessarily be superior to http://cgi.ebay.com/ebaymotors/ws/eBayISAPI.dll?ViewItem&item=150487104197&ssPageName=STRK:MEWAX:IT - These ? $75 complete (includes shipping) for spacers 25mm/1" thick. Hubcentric as well.

|

Posted By: Car-2-Lo

Date Posted: 20 July 2011 at 7:57am

|

No Patty, if you want performance for autocross get your self decent light weight racing wheels with proper offset !

If you want looks only (like me  ), then go with US Alcoa 6061t6 billet aluminum. ), then go with US Alcoa 6061t6 billet aluminum.

Those for $75 does not say "made in USA" ? |

Posted By: Patrick

Date Posted: 21 July 2011 at 2:54pm

|

I found some feedback on these spacers http://g35driver.com/forums/g35-coupe-v35-2003-07/381636-my-review-ebay-wheel-spacer.html - Here . Seems like people are happy with them.

|

Posted By: Patrick

Date Posted: 21 July 2011 at 4:21pm

|

And here's a good tip for anyone who's experienced vibration while using hubcentric wheel spacers... http://g35driver.com/forums/v36-diy/293371-diy-wheel-spacer-vibration-fix.html - DIY: Wheel spacer vibration fix I wouldn't bother at all with non-hubcentric wheel spacers. I think you'd just be asking for trouble.

|

Posted By: Patrick

Date Posted: 22 July 2011 at 12:02am

|

I ordered two pairs of these wheel spacers tonight. One pair for the back of the duke, and a second pair for another club member (who shall remain nameless in case he can't bear the shame).

|

Posted By: Romeo

Date Posted: 22 July 2011 at 3:07pm

Classy! Now I want to know though... Oh well, I remember where everyone's rims were sitting before. I'll just take note if anyone's move out.  ------------- Never shift into reverse without a back-up plan. |

Posted By: Colby

Date Posted: 24 July 2011 at 11:03pm

|

Patrick, I just found a topic on Pennock's about bearings and hubs which might interest you. http://www.fiero.nl/forum/Forum2/HTML/108566.html - http://www.fiero.nl/forum/Forum2/HTML/108566.html ------------- 88 Formula 5 speed |

Posted By: Romeo

Date Posted: 25 July 2011 at 12:09am

It's ok Patty, you'll be happy to hear that in order to maintain my mudder rims and tires, I have a spacer that will be taking my 8-lug bolt pattern down to a 5-lug.  ------------- Never shift into reverse without a back-up plan. |

Posted By: Patrick

Date Posted: 25 July 2011 at 12:39am

|

Thanks Colby, that eBearing fella is a pretty smart cookie. Of course, the whole time I'm reading that thread I'm expecting to see something about 1" wheel spacers being a big no-no. After reading what the eBearing fella was saying, maybe I'll just stick to using my hard street tires on the autocross track.

|

Posted By: Colby

Date Posted: 25 July 2011 at 1:16am

Yeah, it does kind of make you think. At least with autocross we're only exploring the car's limits for maybe 7 minutes worth of driving a day. If Brian hasn't had any issues yet, they can't be too bad. It does make me feel better about sticking with my current tires on the lighter 14" rims, though, I had considered running something wider and stickier. ------------- 88 Formula 5 speed |

Posted By: Romeo

Date Posted: 25 July 2011 at 7:18pm

|

I enjoyed reading about the brief discussion on converting to an A3/A6 set-up though. As was mentioned, this would strengthen the bearings to the point where the weakpoint became the ball-joints. ------------- Never shift into reverse without a back-up plan. |

Posted By: Zac88GT

Date Posted: 27 July 2011 at 9:19am

|

There seems to be a lot of confusion around wheel spacers

with bearing loading. If what you are asking is: "Is there any difference in bearing loading between a wheel with the correct offset and a wheel with a different offset and a spacer to compensate?" then the answer is NO. If you were to bolt the proper wheel to the bearing hub, and the offset wheel, spacer, and another bearing hub together, they would be dimensionaly identical as would the forces being transmitted through them. Where the added bearing loads come in is when you choose wheel + spacer offsets that are different from the original wheels. Typically people want to put wider wheels on, but due to interference with the strut they need to buy wheels with a more negative offset. This moves the centerline of the wheel further away from the bearing which will increase the moment the bearing is required to support. Interestingly, increasing the tire diameter will cause added bearing loads due to lateral forces, but I've never seen this brought up before. |

Posted By: Patrick

Date Posted: 27 July 2011 at 10:29am

|

Yes, that's what I was asking. I was using the word "stress", but "load" is probably the proper term.

< Patty dances a jig around the room > That's exactly what I was suggesting. Now Zac, I gotta ask... What qualifications do you have to make this dissertation? I didn't have any formal "physics" education to back up my arguments, so nobody believed me.

|

Posted By: Zac88GT

Date Posted: 27 July 2011 at 10:57pm

-I have an advanced diploma in mechanical engineering technology. -I'm a registered graduate mechanical technologist with ASTTBC. -I am now only one semester away from a bachelors degree in mechanical engineering. Glad I could shed some light on the subject

|

Posted By: Colby

Date Posted: 28 July 2011 at 1:28am

|

Interesting way of looking at it, though I'm having trouble grasping how it's dimensionally identical if, on the wheel with the spacer, the wheel's spokes are further away from the center of the car than the wheel with the proper offset. Doesn't that matter? I came to my conclusion by taking a look at the simplest case where gravity is the only force (ie. the wheel is off the ground). In this case I feel certain than the wheel with the spacer will be exerting more torque on the bearing. Despite the end of the wheel ending up in the same spot as the wheel with the proper offset, more of the mass is further away from the bearing than the wheel with no spacer. I tried to make it clear to Patrick when I spoke with him that I wasn't even considering what happens when the car is accelerating (whether that's around a corner or in a straight line), things just get too confusing for me then. ------------- 88 Formula 5 speed |

Posted By: Patrick

Date Posted: 28 July 2011 at 12:06pm

|

Thanks Zac, all input into this discussion is appreciated, especially when it agrees with my stance.

|

Posted By: Patrick

Date Posted: 28 July 2011 at 12:13pm

|

That's true Colby, but I don't recall either one of us (or anyone else involved earlier in the discussion) making an issue out of that in particular.

|

Posted By: Colby

Date Posted: 28 July 2011 at 4:31pm

Yes, but I wasn't sure if I had already made that clear in this topic. ------------- 88 Formula 5 speed |

Posted By: Zac88GT

Date Posted: 28 July 2011 at 7:44pm

Yes the position of the spokes will have an influence on the center of gravity (CG) of the wheel and thus influence some of the dynamic loading that the bearing supports. However, it is insignificant in the grand scheme of things because of the minimal change in CG, and the wheel only weighs ~15lbs compared to the 750lb corner weight. If you want to take the spoke position into account then you'll need to know what brand of wheels they are, their center of gravity, their mass moments of inertia, tire weights, tire stiffness and moments of inertia, and a thousand other parameters to model the multi-degree of freedom dynamic system. Formula 1 engineers "might" consider it but I doubt it. Your intuition is correct but you need to look at what the greatest forces involved are. The force from the 15lb wheel will act through the center of gravity, where the 750lb force of supporting the car in that corner will act through the center of the contact patch (the center of the wheel) and not the center of gravity. Hope that helps. |

Posted By: Colby

Date Posted: 28 July 2011 at 11:42pm

Thanks for clearing that up.

------------- 88 Formula 5 speed |

Posted By: Patrick

Date Posted: 09 September 2011 at 9:13pm

I finally picked up these 1" spacers from the fella who's address I use in Blaine for any/all of my US eBay orders. Ended up costing $73(Cdn) total for each pair. One pair for me, and one pair for another club member who I'll try and get to show and tell at the meeting. I like 'em! Nicely made, don't look cheap. Pushes the rear wheels out so that the tires just barely stick out beyond the fender lip. Very manly, good for 3/10's off my next autocross run. Yeah yeah, I should've taken before and after pictures... but I didn't. So you'll all have to line up in person tomorrow at the club meeting to gawk in amazement.

|

Posted By: Colby

Date Posted: 09 September 2011 at 9:47pm

Actually, if anything, expect to hit a couple more cones with your rear wheels now.  ------------- 88 Formula 5 speed |

Posted By: Patrick

Date Posted: 09 September 2011 at 10:03pm

|

You'll be having the same issue when you put the wheel on your car with http://www.westcoastfieros.com/forum/forum_posts.asp?TID=2659&PN=1 - the proper offset .

|

Posted By: Patrick

Date Posted: 11 September 2011 at 3:54pm

|

I had a chance to test the wheel spacers last night going and coming back from the club meeting. I'm happy to report that the hub-centric part of them works very well. I didn't go crazy, but I had the duke up to 120 km (for short spurts between congestion on the freeway) and there was no added vibration at all. I'm pleased.

|

Posted By: Car-2-Lo

Date Posted: 12 September 2011 at 7:33pm

Thanks Patrick Yesterday I installed the wheel spacers on RBS in front to have the wide track look, Fred and I pushed RBS inside the garage and there no vibration and really smooth, RBS is happy

------------- Johnny-B-Good

|

Posted By: Patrick

Date Posted: 12 September 2011 at 8:11pm

|

Oh no, what did Fred hit this time?!!! |

Patrick wrote:

Patrick wrote: