|

Distributor pickup sensor diagnostics |

Post Reply

|

| Author | |

Dawg

Senior Member

Joined: 15 August 2009 Location: Canada Status: Offline Points: 988 |

Post Options Post Options

Quote Quote  Reply Reply

Topic: Distributor pickup sensor diagnostics Topic: Distributor pickup sensor diagnosticsPosted: 14 November 2009 at 5:29pm |

|

In the course of doing our engine swap we ran into some starting problems. In the end, it was the "pickup coil". After talking to David I realized that this is an ongoing problem for many.

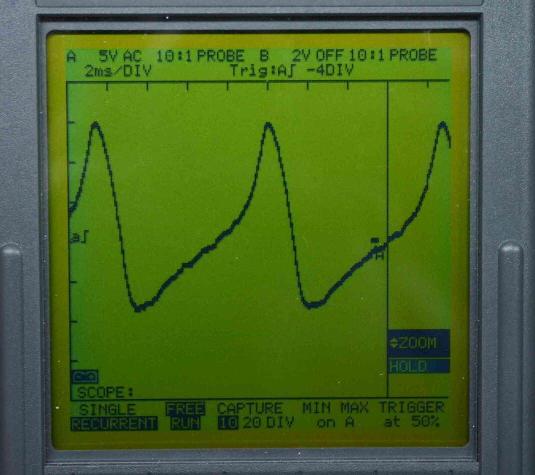

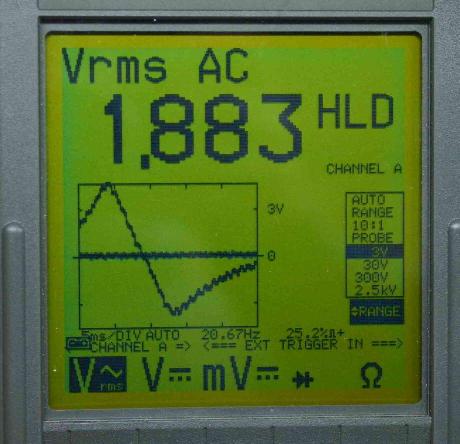

I thought I would dive right in and see what I could come up with. I dug into Davids goodie box and tested several sensors. This included units that we knew worked fine. The first thing to check is the windings themselves. This is done with an ohm meter. If you test across the two connections you should get between 400 and 1200 ohms. Anything less than 400 means the windings are either burnt out or of questionable quality. I might add here that I have yet to find a bad set of windings and I can tell you some of them looked like they had spent some time at the bottom of a lake. So, that's the easy part. The other aspect of testing these sensors involves measuring the amount of voltage they produce at relatively low RPM's. I've decided that 200 RPM would be a good number. My readings at that RPM are 1-2.5 volts AC. This is using a TRUE RMS DVM (digital volt meter). Using an older styled meter may not give the same results. My research so far would suggest that anything under 1.3 VAC is trouble waiting to happen. My dead alternator was putting out 1 VAC. So what's causing these units to malfunction you say? If the windings are good, the only other factor is the magnet that's spinning with the shaft. The magnets used appear to be cheap ceramic types. They aren't known for their longevity. I might try and source some better magnets in the future. I've attached some images of the readings from an actual test. Cheers, Damien This is the waveform and then the voltage reading at 200RPM. So this would be a good one.   |

|

|

You dream it up....I'll make it

|

|

|

|

Post Reply

|

|

| Tweet |

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |