The ultimate ignition system

Printed From: West Coast Fieros

Category: Technical Topics Forum

Forum Name: Technical Questions and Discussions

Forum Description: Got a technical question about your fiero? ask it here.

URL: http://www.westcoastfieros.com/forum/forum_posts.asp?TID=1617

Printed Date: 14 April 2025 at 1:34pm

Software Version: Web Wiz Forums 12.01 - http://www.webwizforums.com

Topic: The ultimate ignition system

Posted By: Dawg

Subject: The ultimate ignition system

Date Posted: 23 November 2009 at 9:40am

|

i'm in the process of building a trouble free V6 ignition system. I've been testing various stock parts and find the whole arrangement to be much less than dependable. Basically it comes down to parts that are not over rated enough to function dependably in the hot Fiero engine compartment. The heat makes the whole system degrade and eventually makes output levels fail. The total solution involves getting the various parts as cool as possible while doing modifications to get more output than you need to simply function. That way when the various parts get old and you're out on a hot summer day there's still plenty of head room left to keep the motor purring along. I'll post some images as the project goes along. I know this has been a real problem for many Fiero owners. I plan to beef up the pickup sensor, put a nice heatsink under the ignition module and install a spike supressor between the coil and distributor. I will test before and after to make sure I'm actually getting somewhere. Stay tuned. PS. If there is any interest, I could set up a demo for one of the club meetings. t would bring my test gear and compare old and new. DG ------------- You dream it up....I'll make it |

Replies:

Posted By: Patrick

Date Posted: 23 November 2009 at 10:31am

|

Damien, I don't know whether you've ever seen http://www.westcoastfieros.com/forum/forum_posts.asp?TID=949&PN=5 - This thread in this forum. I posted the same thing http://www.fiero.nl/forum/Forum2/HTML/095917.html - at PFF and there was a good exhange of information, including http://www.fiero.nl/forum/Forum2/HTML/096031.html - a spin-off thread which described the complete relocation of the ignition module and ignition coil away from the engine/heat. That might be the "ultimate" way to go.

Sounds good to me!

|

Posted By: Romeo

Date Posted: 23 November 2009 at 10:57am

|

That would be SO gnarley. ------------- Never shift into reverse without a back-up plan. |

Posted By: Patrick

Date Posted: 23 November 2009 at 11:04am

|

Tristan, us old guys require a translation.

|

Posted By: Car-2-Lo

Date Posted: 23 November 2009 at 11:24am

That's GROOVY

|

Posted By: Patrick

Date Posted: 23 November 2009 at 11:29am

Okay, I can dig it!

|

Posted By: Capt Fiero

Date Posted: 23 November 2009 at 11:30am

|

Pat I added a reply to the other thread, its been over a year, have you fried a module due to exhaust heat yet? ------------- Capt Fiero 88 Fiero GT 5spd V6 Eight Fifty Seven GT V8 5spd. |

Posted By: Patrick

Date Posted: 23 November 2009 at 11:46am

|

No sir!

|

Posted By: grokan

Date Posted: 23 November 2009 at 10:53pm

|

I've never had a problem with my ignition module... It's been in there 2

years and it's a Borg and Warner piece ------------- Lets get it sideways |

Posted By: Capt Fiero

Date Posted: 23 November 2009 at 11:08pm

|

I hope Dawg doesn't mind, but if this is any idea of the direction he is going with his parts, I can't wait to see what results.

------------- Capt Fiero 88 Fiero GT 5spd V6 Eight Fifty Seven GT V8 5spd. |

Posted By: Dawg

Date Posted: 23 November 2009 at 11:22pm

|

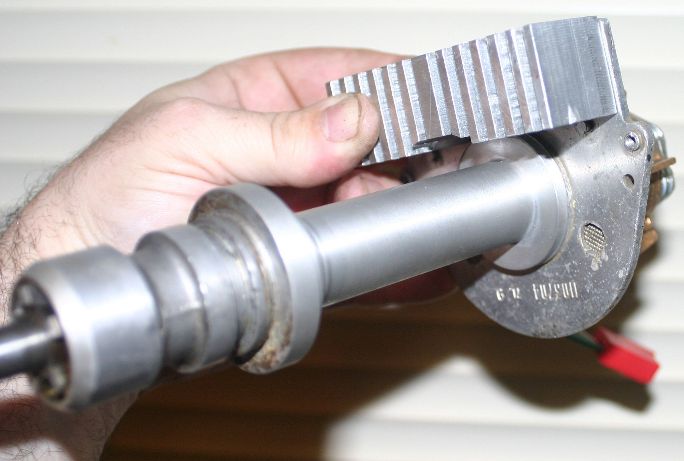

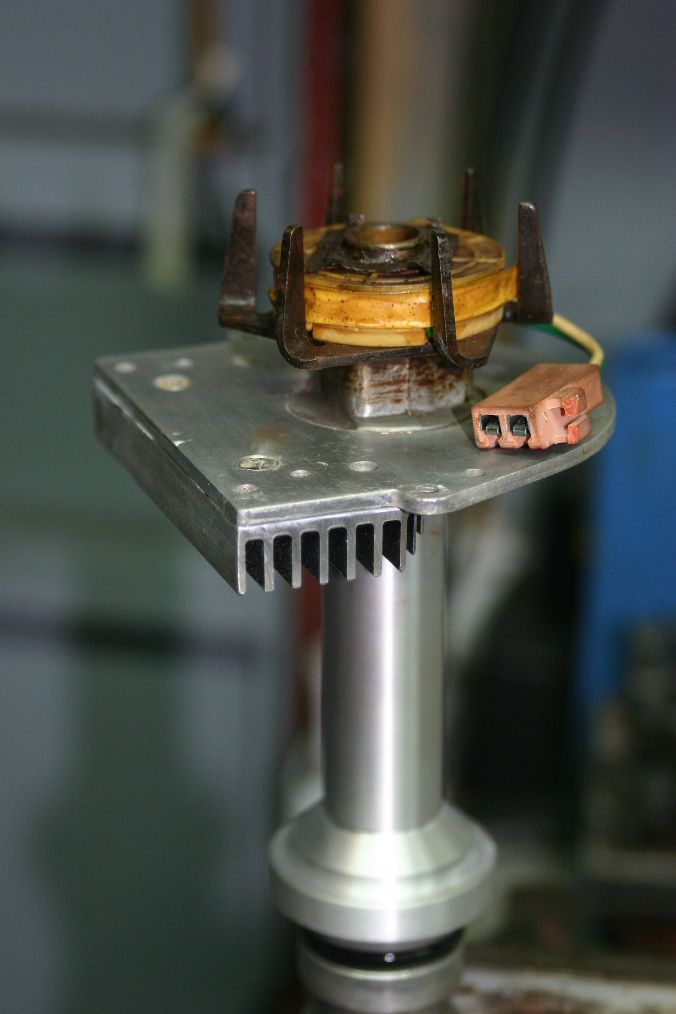

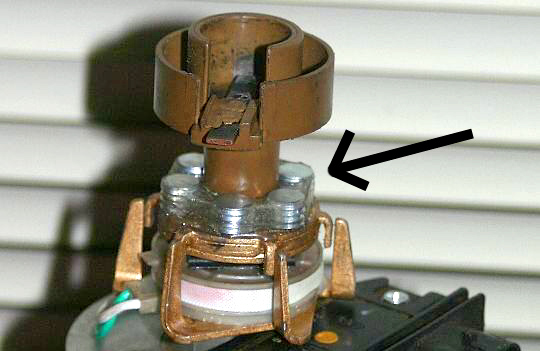

Well Dave, wait no more. The first prototype is almost done. Have a look.    Nice.....eh? And it should function as good as it looks. DG ------------- You dream it up....I'll make it |

Posted By: Capt Fiero

Date Posted: 23 November 2009 at 11:27pm

|

Holy Crap look at that hunk of metal, I don't think a module ever could heat that thing up. At the very least it would keep the temperature at a much more stable rate of increase and decrease. Should be really interesting. There is another mod to the dist shaft we should also talk about. The plate that the module and such is mounted to, is just pressed onto the dist shaft. We might want to look into what it would take to make it more secure and then making a nicer machined transition between the shaft and the plate. I have a simple idea in my head, but will have to talk to you to find out if it is cost effective to do it. ------------- Capt Fiero 88 Fiero GT 5spd V6 Eight Fifty Seven GT V8 5spd. |

Posted By: Romeo

Date Posted: 24 November 2009 at 12:02pm

Seriously guys? lol ------------- Never shift into reverse without a back-up plan. |

Posted By: Dr.Fiero

Date Posted: 24 November 2009 at 8:12pm

On that note.... I've had at least 1 or 2 distributor failures over the years that were attributable to it being pressed on. A fine layer of corrosion can build up between the two surfaces. This creates a layer of resistance that drops the voltage to the module (since it grounds via the plate). That increases the current, which increases the heat! Bad all around. One of 'em was a real crazy maker. Until I figured out WTF was going on - this guy would go out in the morning in the cold season before he drove off to work, and stick a hair dryer under his distributor to HEAT it up! Car would then start fine. He had to go out and run the car for 10 minutes or so every 3 hours while he was at work, or it wouldn't start at the end of the day! As a fix, I ended up drilling a small hole and tapping it, then putting a screw in, right where the plate met the body. Crude, but it worked. :) |

Posted By: CFoss

Date Posted: 24 November 2009 at 9:15pm

|

The spike supressor. what did you have in mind..RC snubber, or varistor? You think transient overvoltages are killing the ig module? I haven't looked at the kickback on the Fiero coil. They can be pretty high though (30-60V and fast) on other cars, so the Fiero's probably not different. The relocation thing...the signal from the pickup would have to be protected in a noisy environment...twisted pair or maybe coax would work. Otherwise relocation should work well. Chay ------------- 86 SE 3.4 |

Posted By: Dawg

Date Posted: 24 November 2009 at 10:09pm

|

Making a small weld to keep the two pieces as one would not be a bad idea. I'll try and do that on the next one. As for the supressor, I'm thinking an MOV. They come in different voltages and they're pretty tough. I'm convinced that voltage spikes coming from the coil could be killing the odd ignition module and weakening them all. This module is old school and very small. There simply isn't enough space there to have effective protection. I bet there isn't any. My digital scope has a built in Minimum/Maximum reading feature. It's fast too. It should pick up and record any big spikes. After I get Michelle's car back on the road, I'm going to set up an experiment where I'll leave a full ignition setup working for several hours with the scope watching. Hopefully I can get an idea of the extent of the problem. I've actually watched what looks like spikes showing up on the scope. The effect is much worse with an MSD coil. In fact, those coils make the ignition module work much harder than OEM coils do. They're brutal. Spark real good though. Here's distributor #1 ready for action. It goes in tomorrow. Thanks to Dave for lending us his for a while. You're the best man! DG    ------------- You dream it up....I'll make it |

Posted By: grokan

Date Posted: 24 November 2009 at 10:18pm

|

lol thats a monster, would it be possible to just relocate

the ignition module? ------------- Lets get it sideways |

Posted By: Patrick

Date Posted: 24 November 2009 at 10:27pm

|

Yes.

|

Posted By: Patrick

Date Posted: 24 November 2009 at 10:35pm

|

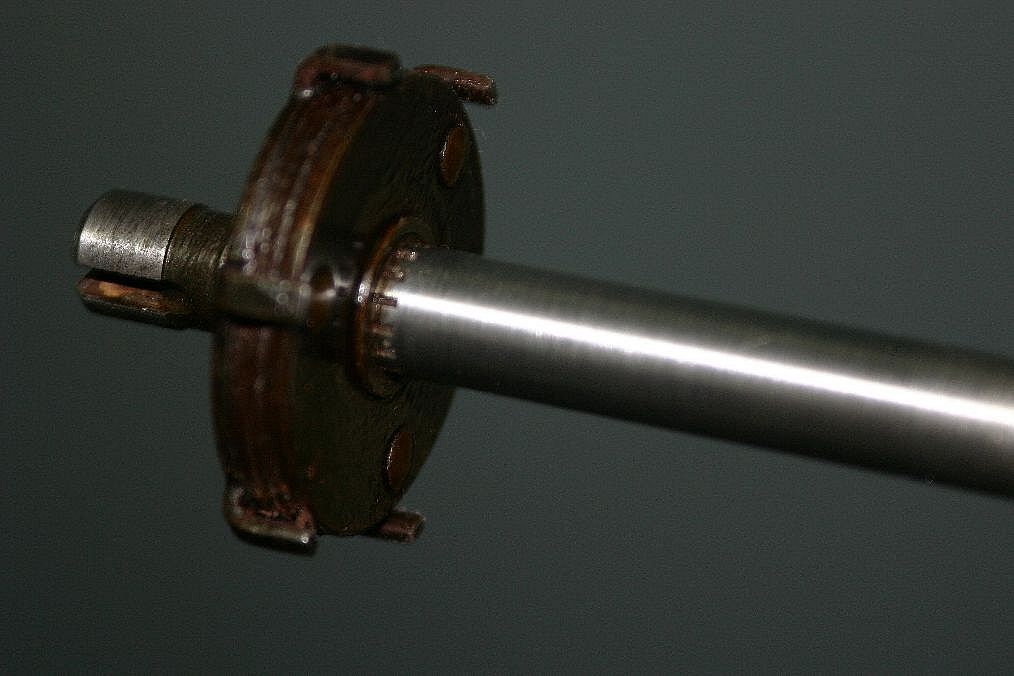

Damien, what are the multiple round silver things, and what function do they serve?

|

Posted By: Capt Fiero

Date Posted: 25 November 2009 at 12:22am

|

Those are Rare Earth Magnets. The pickup coil relies on the magnets in the head of the dist shaft to do its work. When those magnets get weak the cause the pickup no to work right. I'll let Damien explain it better. However in principle it should allow out pickup coil to function much better and last a great deal longer. ------------- Capt Fiero 88 Fiero GT 5spd V6 Eight Fifty Seven GT V8 5spd. |

Posted By: Dawg

Date Posted: 25 November 2009 at 4:41am

|

In my humble opinion, if you're going to try and relocate, you're better off going to a different system all together. If you move this ignition unit, you'll need to mount it on a heat sink anyway, so why not leave it where it is. As for the magnets, yes, rare earth magnets inside steel cups pointing downwards. Next one will have a custom enclosure machined for the magnets. This will make them easier to mount. And yes, more magnetism, more signal from the pickup sensor. Rare earth magnets last a LONG time too. DG ------------- You dream it up....I'll make it |

Posted By: Matt

Date Posted: 25 November 2009 at 1:18pm

I suppose if you relocated it, it might give you more room to mount a fan or workout some other method of cooling the heat sink. Maybe a PC CPU water cooling system mounted to the module?  ------------- I wanna go fast. |

Posted By: Patrick

Date Posted: 25 November 2009 at 3:14pm

|

Is the relative position of the magnets on the head of the distributor shaft important? If so, how do you know exactly where to place them?

|

Posted By: Patrick

Date Posted: 25 November 2009 at 3:23pm

|

Dave, I wish you hadn't closed http://www.westcoastfieros.com/forum/forum_posts.asp?TID=949&PN=1&TPN=1 - the other thread . I think it's great that there's something/anything being discussed that's generating a little more traffic than usual around here. That's a good thing!

|

Posted By: Capt Fiero

Date Posted: 25 November 2009 at 3:30pm

|

Ok If you honestly feel that both are actually justified, I have re-opened it. ------------- Capt Fiero 88 Fiero GT 5spd V6 Eight Fifty Seven GT V8 5spd. |

Posted By: Patrick

Date Posted: 25 November 2009 at 3:36pm

|

Thanks Dave. No doubt both threads will peter out on their own shortly, but it's nice that they can both now die a natural death.

|

Posted By: Dawg

Date Posted: 25 November 2009 at 5:41pm

|

The magnets need to be as balanced as possible. Don't forget, the shaft turns at half the engine RPM. So 6000 RPM means the shaft will be at 3000 RPM. We're getting into a range where an imbalance will either cause vibration that will destroy the bushing over time or cause the magnets themselves to fly off and explode the cap and rotor. All nasty stuff which is why I'm designing a custom housing that will prevent such things. For the prototype I was very careful how I placed the individual magnets. I also wrapped a wire around them to make sure they stayed put. Lots of epoxy to hold it all together. DG ------------- You dream it up....I'll make it |

Posted By: Dr.Fiero

Date Posted: 25 November 2009 at 6:00pm

|

What about from a magnetic polarity point of view? |

Posted By: Patrick

Date Posted: 25 November 2009 at 6:56pm

|

I don't think you actually addressed my questions. Trade secret?

|

Posted By: Dawg

Date Posted: 25 November 2009 at 9:54pm

|

Ummm....Well basically, balanced means equal spacing between them. Fit as many magnets on there as you can and make sure if you were to cut the rotor in half, there would be the same number of magnets on one side as the other. Is that clearer? As for polarity, I found it does matter. It is trial and error however. I take a reading with the magnets one way, then flip them around and test it again. Once I know the polarity, I take them off carefully and stack them all on top of each other and then stick them to a piece of steel. This makes sure I don't lose track of which way is up. DG ------------- You dream it up....I'll make it |

Posted By: CFoss

Date Posted: 25 November 2009 at 10:23pm

|

If the signal from the reluctor can be improved then remoting becomes easier with the improved signal to noise ratio that would result. Just build a box, extend the connector leads, and heat sink away. Something to try one day I guess. Maybe with a spare dist. I wonder if a MOV might be too slow to effectively damp the coil spike. I suspect the MSD has less inductance and is flowing more current and thus the greater kickback. I built a push pull dc-dc switcher with a 20khz switch frequency and the only thing fast enough to damp the primary spikes was a R-C snubber. Also, the R got hot, as there was a fair amount of energy dissipated (1-2W). I suspect if the MOV works it will get worm in short order, depending on the joule rating. What kid of scope do you have? Fluke scopemeter?? They aren't great at capturing small duration peaks. If you can get one, the portable teks are great. They have a peak detect mode that kicks ass (geek alert). Chay ------------- 86 SE 3.4 |

Posted By: CFoss

Date Posted: 25 November 2009 at 10:27pm

|

I looked at your other thread, 1.8V, approx sinusoid = 2.5V peak...not too shabby. It should hold up pretty well for remoting I'd guess. Time to run a bunch of wire around the engine bay and see how much crap it picks up with the scope. C ------------- 86 SE 3.4 |

Posted By: Patrick

Date Posted: 25 November 2009 at 10:42pm

|

Ummm... not really. I'm not sure why this is so difficult to get across. Okay, once more... There's six poles (for lack of a better term) on the head of the distributor shaft. What determines where the magnets sit in relation to the poles? If you were to shift them all over an eighth of an inch for example, would that throw it all out of whack. (non-geek alert) Is my question any clearer?

|

Posted By: Dawg

Date Posted: 25 November 2009 at 11:12pm

|

There's six poles (for lack of a better term) on the head of the distributor shaft. What determines where the magnets sit in relation to the poles? That's a better question. I get it. Simple answer, doesn't matter. You're magnetizing the flat piece of metal they're sitting on. Ideally, the rotor is channeling all the magnetism to the poles (fingers). Happy now?.....:) I suspect if the MOV works it will get worm in short order, depending on the joule rating. You can buy some pretty big MOV's these days. We'll see. What kid of scope do you have? Fluke scopemeter?? They aren't great at capturing small duration peaks. If you can get one, the portable teks are great. They have a peak detect mode that kicks ass (geek alert). Yup, Fluke Scopemeter. The scope display is rather slow yes but you can sometimes catch stuff in over sample mode. Also, the DMM's Min/Max feature seems to be much faster. I hope the dissipated energy in the MOV will be reasonable. Time will tell. I will be testing as I go. I have an analog scope in storage I can get if need be. DG ------------- You dream it up....I'll make it |

Posted By: Patrick

Date Posted: 25 November 2009 at 11:35pm

|

Getting there. So it doesn't matter where the rare earth magnets sit in relation to the existing magnets in the head of the distributor shaft? Or do the rare earth magnets attract/repel themselves into the optimum position? ie... 12, 2, 4, 6, 8, 10 o'clock looking down on the top of the distributor shaft head as opposed to 1, 3, 5, 7, 9, 11 o'clock.

|

Posted By: Dawg

Date Posted: 26 November 2009 at 9:22am

|

Patrick, I understand your question buddy and no, in this case it does not matter. Everything that matters has been revealed. The metal plate acts like a "sponge" if you like, and directs the energy where it's needed. DG ------------- You dream it up....I'll make it |

Posted By: Patrick

Date Posted: 26 November 2009 at 9:31am

|

Interesting. Thanks very much for the info, Damien.

|

Posted By: CFoss

Date Posted: 26 November 2009 at 10:25am

|

From the Megasquirt website:

GM and most other electronic spark driven reluctor electronics trigger on the negative going zero transition after a positive voltage. While they could trigger on the rise that is not how they were designed. Thus polarity of the reluctor signal is critical to proper function. In the GM 7/8-pin HEI, the module converts the AC signal from the variable reluctor pick-up {on pins P & N} in the distributor to a 'square wave' tach signal {on pin R} suitable for MegaSquirt-II. Be sure to get the variable reluctor pick-up wires connected properly. Reversing the variable reluctor sensor wires and thus the polarity of the sensor causes the leading voltage to go negative first and the electronics ignores the positive going transition. Thus trigger signal, if ever recognized, is the falling edge of the voltage as the end of the tooth passes. The only way to get proper triggering at the center of the tooth is to have the positive ½ cycle first (tooth approaching) and the negative ½ cycle last.

So, from this I get that the polarity is critical as DAWG already noted, amplitude is not so important, and the 0 transition should be as clean as possible (Crosses 0 once, not multiple times). If we can acheive this, then remoting is a good posibility. A 0 crossing detector is a good choice to limit interference, which is probably why they used it.

Chay ------------- 86 SE 3.4 |

Posted By: Dawg

Date Posted: 26 November 2009 at 4:37pm

|

As a thank you for Dave lending me his distributor I decided to spiffy it up a little. Good thing I did. The clip holding the pickup coil was only holding on with one side and the upper bushing was basically dry. All fixed and lubed now. See how the shaft was actually scored  All better now  Looking real nice and ready for action  A nice distributor for sure! DG ------------- You dream it up....I'll make it |

Posted By: Capt Fiero

Date Posted: 26 November 2009 at 8:11pm

|

Many Thank You's for setting that up. I should be able to get it back installed in the 88 tomorrow and test fire. Will be nice to be able to fire the car up again. ------------- Capt Fiero 88 Fiero GT 5spd V6 Eight Fifty Seven GT V8 5spd. |

Posted By: Dawg

Date Posted: 26 November 2009 at 8:46pm

|

Well the cleaned up, oiled up, jacked up distributor is in the car and running perfectly. Sure looks good in there too. After I took the car for a short run I popped the hood open and touched the heat sink. It was nice and hot which means it's conducting well and sucking heat away from the ignition module. Mission accomplished. I should add that I have one of those MSD coils. So lots of heat to deal with. I have no idea how these modules survive normally. I guess many don't for very long. DG ------------- You dream it up....I'll make it |

Posted By: Dawg

Date Posted: 26 November 2009 at 8:56pm

|

Some have asked so I will say that I do have enough aluminum to make 6 or 7 heat sinks. I will get them done this week. Those interested can PM me. I'm thinking maybe $50-60 for the heat sink, new hardware, heat sink compound and a paper template to show you where to drill the holes. I'll install it for you for an additional $20. DG ------------- You dream it up....I'll make it |

Posted By: Capt Fiero

Date Posted: 01 December 2009 at 12:47pm

|

SO how is the test mule doing in the wifes car, been able to drive it much? I know she probably won't rev it that high, but have you had a chance to scream the RPMS up for any prolonged sessions? Any chance to get it hot enough for the rad fan to kick on in Traffic? I am sure a lot of interest will be there once people know this is a bonified save your butt item. ------------- Capt Fiero 88 Fiero GT 5spd V6 Eight Fifty Seven GT V8 5spd. |

Posted By: Dawg

Date Posted: 01 December 2009 at 7:49pm

|

Well, I have driven the snawt out or it. Yes a fair bit of 5000-6500 shifting and no problem other than some pinging. Need to see John and get a chip done for this camshaft. I routinely pop the hood and feel the heat sink. It's always about the same temperature no matter how hot the engine is. Our ignition problems are over, simple as that.

------------- You dream it up....I'll make it |

Posted By: Dawg

Date Posted: 20 December 2009 at 4:37pm

|

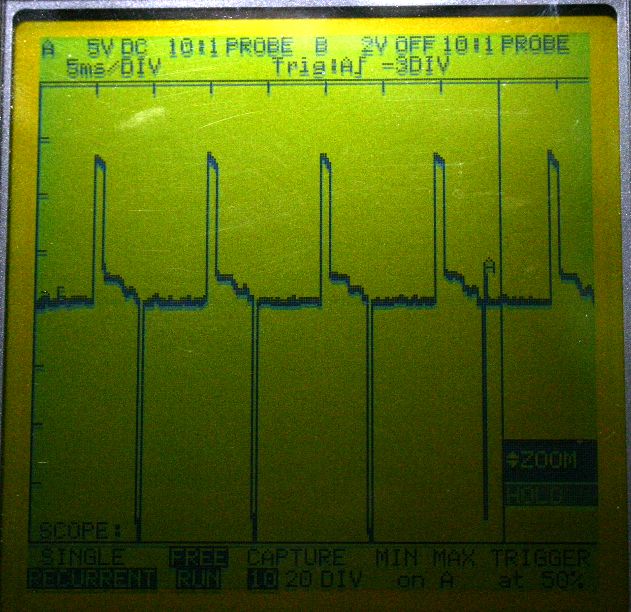

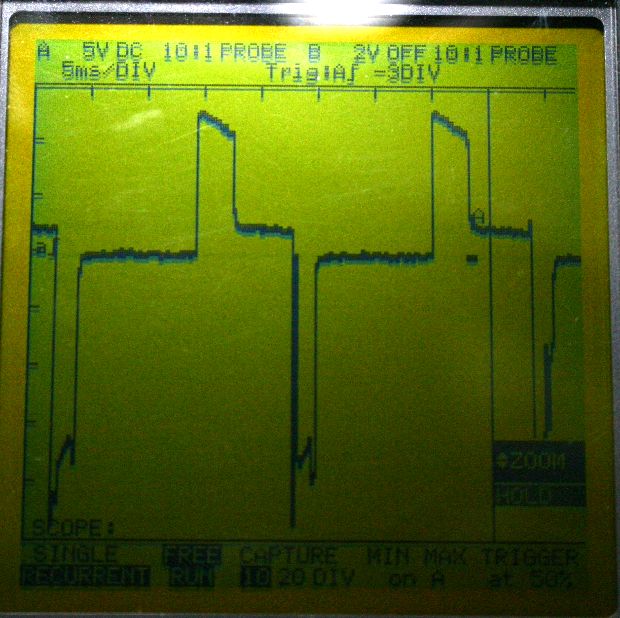

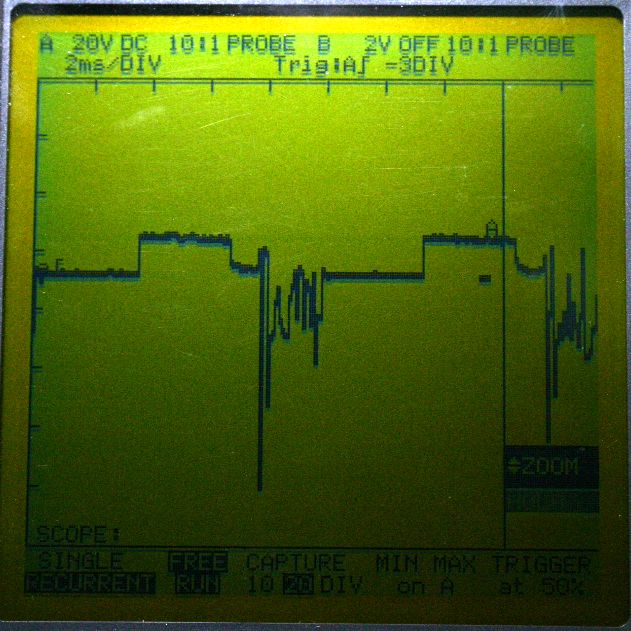

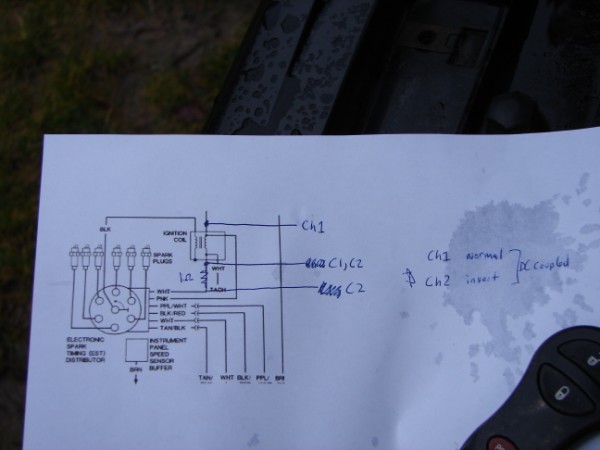

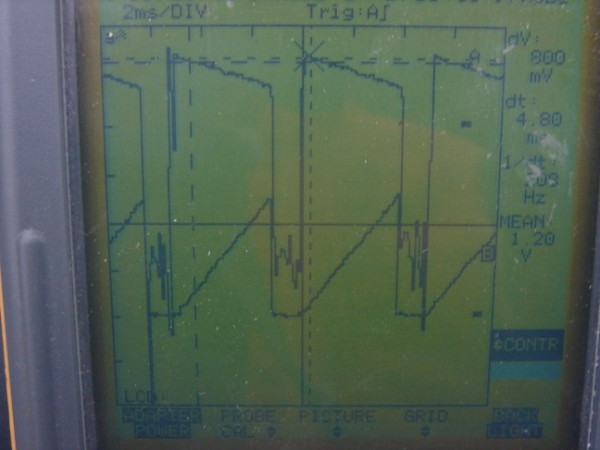

I had some time today to play. I hooked up a full ignition system on the bench and poked around a bit. For the benefit of the techies on board, have a look at this: Here's the signal coming from the ignition unit to the coil. Just starting everything is cold.  You can see the negative going spikes. Here's a little later. Getting warmer.  Even hotter now and I've changed the voltage scaling to attempt a better reading.  70 volts! Things are getting nasty! The actual voltages could be much higher. The display might be showing the limitations of my instrument. I should note, the ignition unit I'm beating on is of questionable condition. Damien ------------- You dream it up....I'll make it |

Posted By: Dawg

Date Posted: 20 December 2009 at 9:23pm

Here's a picture of the latest batch of heat sinks in case anyone is interested. Got a few left, don't know when I'll be making more. Thanks. Damien ------------- You dream it up....I'll make it |

Posted By: Capt Fiero

Date Posted: 22 December 2009 at 8:08am

|

Damien when you get a chance, I'd love to see what your timing does on a timing light now. You new mag system might solve a 2nd problem that most Fiero's have, however I would have to look at in person to see if it does. ------------- Capt Fiero 88 Fiero GT 5spd V6 Eight Fifty Seven GT V8 5spd. |

Posted By: CFoss

Date Posted: 22 December 2009 at 10:20am

|

How is this probe hooked up?...bottom of the coil to common(Ground)? It looks like that's it. I would like to see ch1 across the coil, and ch2 hooked to a current probe (.01ohm maybe, 5A = 50mV signal at max) in the primary to show primary charging current...that would nail it.

I think this module is suspect. To define what I'm talking about, the period where the waveform is high is when the ig module is open circuit. When the voltage is low, but not 0 the current is building in the coil and the module is conducting. The small voltage is due to the saturation voltage of the transistors in the module. Then, the negative going spike is when the energy in the coil primary is transfered to the secondary and a spark occurs.

Now, look at the timing...When it's cold, is it open circuit for 4ms, then charging for 5ms or so (This is the dwell on a points system, btw), then it discharges to the plug over 1-2ms period. Good stuff.

Now look at the last one, the ugly. It's o/c for about the same period, then charging for a very short period of time...1ms or so. This causes a dramatic reduction in spark energy, because the coil only has 1/5 the time to build up energy. The current builds linearly, so 1/5 the current, but the enery is proportionl to the square of the current, so something like 4% of the previous energy is delivered. Not good, and it shows in the discharge waveform, which is very low amplitude and I suspect the spikes are due to multiple crappy arcs.

The dwell is supposed to be fixed in this system...ie, the module is shot.

It probably is not strong enough to deliver a signal to a timing light.

Chay ------------- 86 SE 3.4 |

Posted By: CFoss

Date Posted: 22 December 2009 at 10:30am

|

I was wrong about dwell being fixed...it is controlled dynamically from the ecm...

So, were these screen shot taken at abou the same rpm? Looks close from my count...9ms vs about 9 ms period, so about 2222rpm?

Am I close?

Chay ------------- 86 SE 3.4 |

Posted By: CFoss

Date Posted: 22 December 2009 at 10:54am

|

I read some more via megasquirt, and their typical values for dwell are 2-4ms, depending on the L of the coil used.

For us, if we assume a spark discharge time of 3ms, and dwell of 4ms (Each of these is conservative) we have a total system time of 7ms for each spark. We should be able to maintain this until: 7ms*3sparks/rev = 21ms, 21ms^-1*60 = 2857rpm, at which point the ecm would lower the dwell and the resulting spark time in order to keep it firing on time. So, we get a really good spark at up to 2800rpm, then by 3000rpm, the spark energy is about 1/4 of what it was at 2800 (Because the dwell is /2).

Chay ------------- 86 SE 3.4 |

Posted By: CFoss

Date Posted: 22 December 2009 at 10:57am

|

I keep posting, but I realize this suggests something.

If you need better high rpm energy, get a coil with less L and more secondary windings. This will respond better to lower dwells at higer rpm, but will deliver a lower energy spark at sub 2800rpm.

My guess is this is what the MSD blaster is all about.

Chay ------------- 86 SE 3.4 |

Posted By: CFoss

Date Posted: 22 December 2009 at 1:38pm

|

Oh, yeah, one MORE thing. The amplitude of the reverse voltage on the coil primary will be equal to the spark plug breakdown voltage*ratio of the ignition coil. Essentially, the ignition coil becomes a transformer, with the primary and secondary "disconnected". Therefore the voltage will build on the primary and secondary until one or the other exceeds the voltage level required to drive current...it lets go on the secondary when the spark plug fires.

This means that there is no good way of reducing this spike, because in doing so you'll be absorbing energy which ought to go to the spark plug. The focus should be on attaining a good dwell time, so the spark plug fires once strongly rather than the weak restrike I see in the last of your scope shots. Comments? Chay ------------- 86 SE 3.4 |

Posted By: Dawg

Date Posted: 23 December 2009 at 11:38pm

|

The probe was connected across the two wires coming from the ignition module. So positive 12vdc and the module's pulsing ground. A function generator is triggering the ignition module as a substitute for the pickup coil and there is no ECM, dwell should have been constant. So actually, the high readings are showing the module conducting (closed). As I understand it, this is when the primaries are charging. Somewhere in there the spark should occur....no? If this is so, then the negative going spike is a reflection after the fact. If I get some time after Christmas, I'll see if I can find something to use as a shunt as I have no current probe.

------------- You dream it up....I'll make it |

Posted By: CFoss

Date Posted: 25 December 2009 at 1:56pm

|

I have to try this myself. I thought I had it all figured out, and the change in probe position has thrown me into confusion. I don't get how it works, but I'll try to figure it out with the new info. Chay ------------- 86 SE 3.4 |

Posted By: Patrick

Date Posted: 26 December 2009 at 12:21pm

|

That makes (at least) two of us. Seems as though there's plenty of discussion on this topic... http://www.fiero.nl/forum/Forum2/HTML/105003.html - Here .

|

Posted By: CFoss

Date Posted: 26 December 2009 at 5:30pm

|

I have a new thought which seems to fit. You can confirm it with the current probe. The high voltage corresponds to the dwell. The dwell is long enough that the maximum peak current is reached. This is a module maximum current and protects the module and stops the coil from overheating. The value increased through the years. It started at 5 amps and unded up at 8 amps. I'm not sure where ours fit in. Anyway, when the max current is reached, the voltage across the coil drops to the value required to maintain the current flow which is quite low because the only factor is the parisitic resistance in the coil primary. This drop from high voltage to low slightly positive voltage should be coincident with the ramping current leveling off. Then sometime later, the module interrupts the current flow and the large reverse voltage is the reflected voltage required to fire the plug on the secondary. As the frequency increases, the amount of 'max current' time should decrease until it dissapears. Then the voltage should go from the positive directly to the negative with no intermediate level. I'd be interested in the results of the I probe. It should be quite reveling. I haven't had a chance to read the link. I'll do it when I get a chance. C ------------- 86 SE 3.4 |

Posted By: Dr.Fiero

Date Posted: 26 December 2009 at 5:57pm

|

I have a low amp clamp probe you can borrow.

|

Posted By: CFoss

Date Posted: 26 December 2009 at 10:04pm

|

The clamps might work if it was the right type. All the current to voltage types I've used add delay, so they would show the waveform correctly, but it would not allign to make sense with the voltage waveform and be conclusive. The best way to go is a good old resistor...the trouble is breaking it into the circuit of course. Chay ------------- 86 SE 3.4 |

Posted By: Capt Fiero

Date Posted: 03 January 2010 at 12:14am

|

Damian, when you do sell one, make sure to get the buyer to keep a report on how well it works. Another interesting test would be to take some "bad" modules or pickup coils, and test them in your fancy device and see if the bad parts come back to life. ------------- Capt Fiero 88 Fiero GT 5spd V6 Eight Fifty Seven GT V8 5spd. |

Posted By: Dawg

Date Posted: 03 January 2010 at 7:08pm

|

Well the exact same setup is in Michelle's daily driver. Other than that connector issue, it's been working perfectly. If a problem of any kind pops up I will report it. As far as testing goes. It's going to take a while before I know exactly what good and bad really are. If anyone wants to bring me their suspected dead or old modules so I can beat on them that would be good. Eventually, I will learn how to tell what shape they're in.

------------- You dream it up....I'll make it |

Posted By: CFoss

Date Posted: 17 January 2010 at 4:39pm

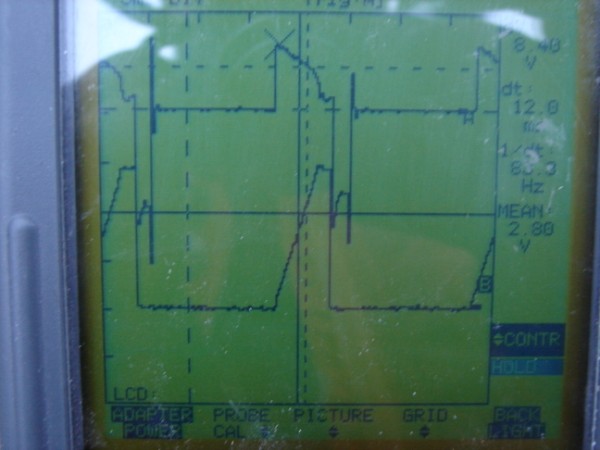

I have an update. Today I was able to do a 2 channel scope of my car like I talked about. Here is the setup: Here it is physically:  Here are the results: Idle:  See how the voltage waveform drops as the current levels off? This is the max primary current I was refering to. The ig module limits the current in the primary to avoid overheating of the coil and the ig module. Then as the primary current drops to 0 the voltage on the primary reverses, indicating a spark has been delivered. reved up:  It's essentially the same, only there is no current leveling off. This is because there is no time for the coil current to reach maximum. It also means the spark energy has been degraded somewhat at this rpm (4k or so). Chay ------------- 86 SE 3.4 |

Posted By: Dawg

Date Posted: 10 February 2010 at 10:37pm

|

Hey John, how did my heat sink and magpack work out? Everything go together easily? DG ------------- You dream it up....I'll make it |

Posted By: Dr.Fiero

Date Posted: 11 February 2010 at 6:13am

|

I'll let you know as soon as I do it.... :) (been working on all the 'other' stuff still) |

Dawg wrote:

Dawg wrote:

There's no reason why a discussion can't take place in two threads on a similar topic. I was hoping to receive a reply from Chay to a question I had asked him there.

There's no reason why a discussion can't take place in two threads on a similar topic. I was hoping to receive a reply from Chay to a question I had asked him there.